- Home

- Machines & Processing lines

- Turnkey processing lines

- Flax tow processing

Flax tow processing

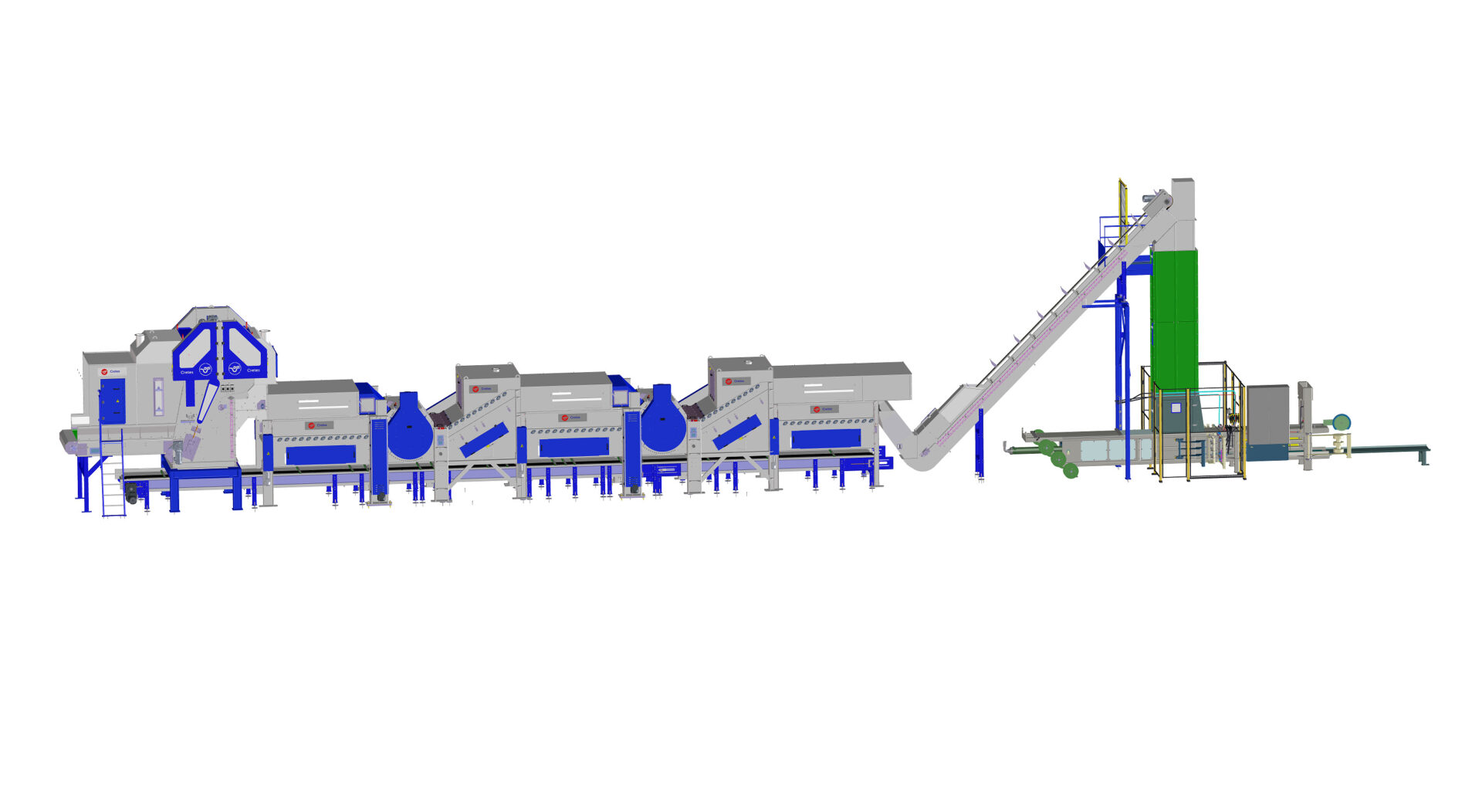

Complete processing line for cleaning of flax tow. A modular design with components for opening, cleaning and baling of flax tow fibres. The standard working width of this line is 1,5m. The length of the line depends on the number of cleaning modules that are installed.

-

-

-

Typically, the flax tow fibres are fed to the line in rectangular bales. After the binding wires have been removed, the flax fibres are opened. This can be done, for example, with a pre-opener (for rough opening) followed by a hopper feeder (for finer opening and dosing). Alternative setups are perfectly possible. The exact layout of a line is always designed in close consultation with the customer.

-

-

The opened flax fibres are entered in a series of cleaning modules. Together with the customer and based on the desired capacity, degree of cleaning, machines to recuperate, etc. the best suitable layout is determined. A common method of operation after the opening, is a combination of a horizontal shaker followed by a cleaning drum with inclined shaker and a horizontal shaker at the very end. Numerous variations exist due to the modular design of these components.

The purpose of the shakers and drums is to comb the fibres, to break and loosen the shives, and finally to separate these shives as much as possible. Underneath the cleaning modules a long conveyor belt collects these shives and transports them to a central extraction point.

During operation there is a certain generation of dust. Multiple openings are installed on the line for the connection of a dust extraction system. In this way, dust can be removed efficiently and both the flax and the area around the line remain dust-free.

-

-

The clean fibres are pressed into rectangular bales at the end of the line. The fibres can be transported to the baling press by means of an air transport system, but often the baling press is positioned in line with the rest of the machines. This makes it easy to bring the fibres into the filling chute of the press with an inclined belt conveyor. Simple but most effective!

The bale presses are built by our sister company Valvan. They are distributed by Cretes and they can be integrated into a complete processing line.

-

-

Over 100 years

of experience

-

Turnkey

Projects

-

Company of the

Valtech Group

This site uses cookies. By continuing to browse the site, you are agreeing to our use of cookies. Find out more.